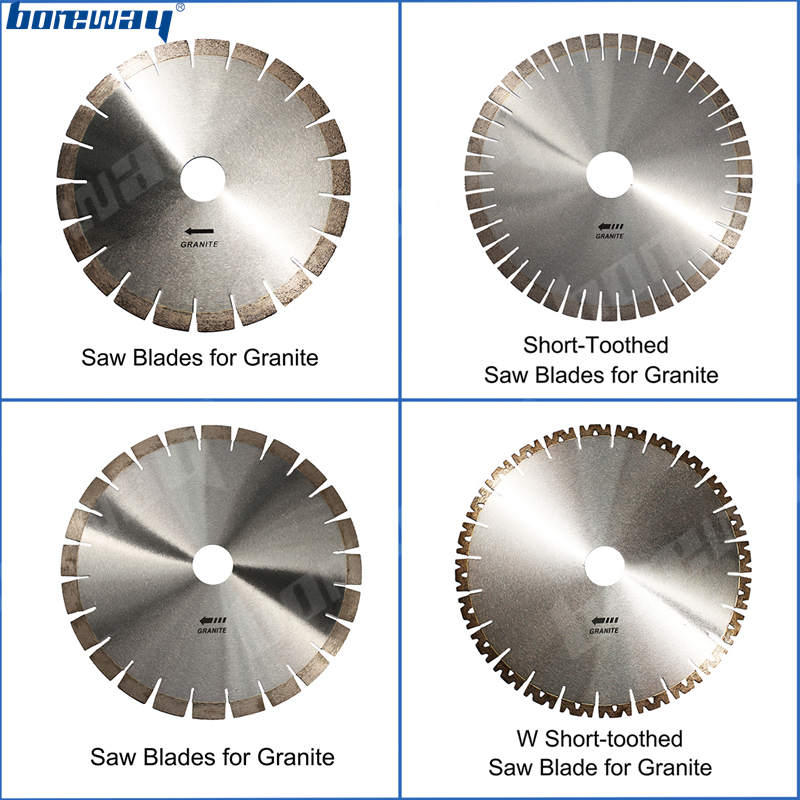

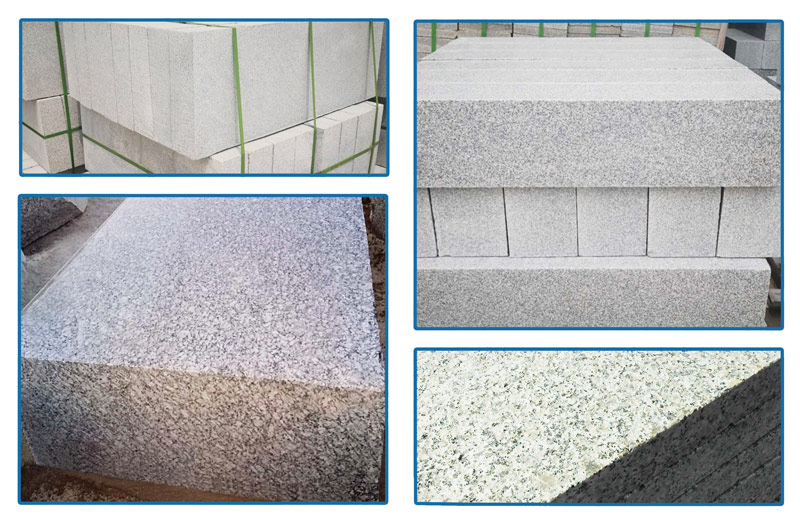

Diamond saw blade is mainly used to cut hard and brittle stone, it is one of the main tools for producing natural stone plate,

Boreway manufacturers will introduce the reason why the diamond matrix is deformed during the manufacturing process. If you do not pay attention during the manufacturing process, there will be some small mistakes

Diamond saw blades for quartz suitable for bridge cutting machine, manual handling cutting machine or table cutting machine.

Advantage:

1. The substrate is made of 65 manganese steel, which is heat-resistant, low-temperature resistant and good toughness

3. Used for dry-cut granite, bluestone and other medium and high hardness stones

4. Cutting of non-metallic brittle and hard materials such as brick walls and concrete

5. Used for stone steel hanging project, wall slotting.

It can be seen from the technical standard requirements of the diamond saw blade matrix that to achieve the elastic limit and hardness index of the matrix, for the diamond saw blade with 65Mn used as the matrix material, the heat treatment method should be quenching + medium temperature tempering.

However, the quenching of the diamond saw blade matrix has a very prominent feature, that is, the quenching deformation and cracking tendency are large.

The causes of deformation are:

1. Heating whether it is air or salt bath, more or less thermal convection will impact the film base and cause heating deformation.

2. Cooling due to the different cooling speeds of the various sections of the cross section causes temperature differences, resulting in uneven volumetric shrinkage of the steel, which leads to the formation of thermal stress. In addition, during quenching, the supercooled austenite of the steel changes to martensite There is a change in specific volume which causes a phase change and deformation caused by tissue stress.

Copyright © boreway.com

Home |

About Us |

Products |

Quality Control |

News |

FAQ |

Contact Us |

Site Map

Copyright © boreway.com

Home |

About Us |

Products |

Quality Control |

News |

FAQ |

Contact Us |

Site Map