,

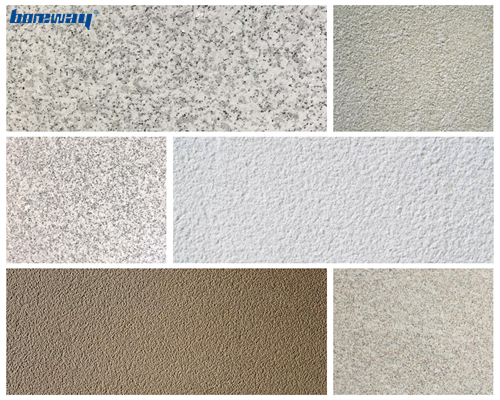

What is granite sandblasting surface?

Sand blasting treatment of natural stone (stone sand blasting surface) is to use diamond, quartz sand, river sand and other abrasives with edges and corners to impact the stone surface under the drive of compressed air (or water). Sand blasting machine and brazed diamond can be used, brazing alloy crushed bullet roller a kind of stone surface similar to glass grinding effect is obtained by processing stone Mode of work.

The application scope of stone sandblasting is very wide. It can not only be used in the processing of natural slate products such as thin plate and specification plate, but also can be used in the processing of special-shaped stones such as lines, columns, railings, steps and corners. Moreover, sandblasting is also widely used in stone carving.

At the same time, the stone sand blasting processing, like other processing methods, can not only carry out small-scale sand blasting processing, but also large-scale sand blasting processing. Of course, stone sandblasting is not only used for the surface processing of stone as decorative surface, but also can be used in the repair of stone. For some installed stone, if there are serious stone lesions that cannot be repaired, the surface sandblasting can also be used.

The process of stone sandblasting: the process of stone sandblasting is very simple. If it is full area sandblasting, it only needs to sandblast the rough and flat slate directly.

In case of local sandblasting, the part that does not need sandblasting must be wrapped with rubber sheet or other sandblasting protective film before spraying.

At present, there are two main methods for stone sand blasting, one is manual sand blasting, the other is machine sand blasting. Among them, manual sandblasting is usually dry sandblasting machine, and machine sandblasting is divided into dry sandblasting machine and liquid sandblasting machine. Dry sandblasting machine can be divided into suction type and pressure type.

Suction type dry sand blasting machine: suction type dry sand blasting machine is a negative pressure formed in the spray gun by the high-speed movement of air flow with the power of compressed air. The abrasive is sucked into the spray gun through the sand conveying pipe and shot out through the nozzle, and then sprayed to the processed surface to achieve the expected processing purpose. In the suction dry sand blasting machine, compressed air is not only the power of feeding, but also the power of accelerating.

Press in dry sand blasting machine: the press in dry sand blasting machine is powered by compressed air. Through the working pressure established in the pressure tank by compressed air, the abrasive is pressed into the sand conveying pipe through the sand outlet valve and shot out through the nozzle. The abrasive is sprayed to the processed surface to achieve the expected processing purpose. In the press in dry sand blasting machine, compressed air is not only the power of feeding, but also the power of accelerating.

Liquid sandblasting machine: compared with dry sandblasting machine, the biggest characteristic of liquid sandblasting machine is to control dust pollution in the process of sandblasting and improve the working environment of sandblasting operation.

Copyright © boreway.com

Home |

About Us |

Products |

Quality Control |

News |

FAQ |

Contact Us |

Site Map

Copyright © boreway.com

Home |

About Us |

Products |

Quality Control |

News |

FAQ |

Contact Us |

Site Map