,

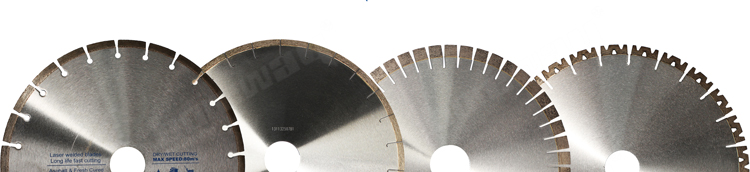

Diamond saw blade is a cutting tool, widely used for cutting concrete wall, refractory, stone, ceramics and other hard and brittle materials.

Diamond saw blade mainly consists of two parts: matrix and cutter segment.

50Mn2V, 75Crl and 65Mn are the main raw materials for the production of diamond saw blade matrix.

45 # steel

Some low-end markets also use 45 # steel.

75 Crl

45 # steel is common carbon steel, 65 Mn is common spring steel and 75 Crl is high carbon alloy steel. Compared with 50Mn2V, 50Mn2V is a medium carbon alloy steel with fine grain, good thermal stability, high strength and toughness, good fatigue resistance and heat resistance.

The saw blade matrix of 50Mn2V material has the advantages of many times of re welding, long service life, difficult deformation of saw blade after welding head, easy repair after deformation and so on. The hardness of the product is gradually improved in the use process. Therefore, 50Mn2V material is widely used in the processing and production of diamond saw blade matrix.

According to the specification classification, the base specification of domestic stone processing saw blade starts from 200 mm, and reaches 3500 mm at most (the largest circular saw blade specification in foreign countries is 5000 mm towel).

Among them, dp200-600ram specification is mainly used for cutting (cutting) of semi-finished plates

The specifications above 650 are mainly used for the sawing of thick plates (columns), such as tombstones and tombstones, and the sawing (plate) processing of waste materials.

Copyright © boreway.com

Home |

About Us |

Products |

Quality Control |

News |

FAQ |

Contact Us |

Site Map

Copyright © boreway.com

Home |

About Us |

Products |

Quality Control |

News |

FAQ |

Contact Us |

Site Map